Ensure Safety and Efficiency: Use a Nitrogen Gas Regulator and Welding Blanket Correctly

Ensure Safety and Efficiency: Use a Nitrogen Gas Regulator and Welding Blanket Correctly

Blog Article

In industries where precision and safety are non-negotiable, using the right tools can make all the difference. Whether you're involved in HVAC maintenance, refrigeration services, or metal fabrication, two essential tools you should never overlook are the Nitrogen Gas Regulator and the Welding Blanket. These seemingly simple devices play a crucial role in enhancing work quality, improving safety, and preventing costly mistakes.

Let’s take a closer look at how these tools work and why incorporating them into your workflow is a smart move.

What Is a Nitrogen Gas Regulator and Why Do You Need One?

A Nitrogen Gas Regulator is a vital device that controls the pressure of nitrogen gas released from a cylinder. Without it, the gas could escape uncontrollably, creating hazardous conditions or compromising the integrity of your work. Nitrogen is often used to purge HVAC systems, test pipelines for leaks, or maintain pressure in refrigeration systems. In each of these scenarios, precision matters.

By attaching a nitrogen gas regulator to your tank, you can deliver a steady, controlled flow of gas at the pressure required for your task. For example, when purging an AC line, using too much pressure can damage the internal components. With a regulator, you ensure that the pressure is just right—efficient and safe.

Benefits of Using a Nitrogen Gas Regulator

Safety First: Controlling gas pressure reduces the risk of explosions, leaks, or damage to equipment.

Extended Equipment Life: Excessive pressure can wear out system components. A regulator helps you avoid this.

Precision Work: With fine-tuned control, you can perform purging, brazing, or pressure testing accurately.

Gas Efficiency: A controlled flow means less wasted nitrogen, which saves money over time.

Using a nitrogen gas regulator not only enhances performance but also ensures that you're complying with industry safety standards. It’s an investment that pays off in both performance and protection.

Understanding the Welding Blanket and Its Importance

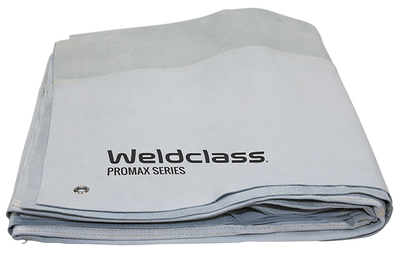

While a nitrogen gas regulator helps control pressure and protect systems internally, a Welding Blanket protects your work environment externally. It acts as a heat-resistant barrier that shields surrounding surfaces from sparks, spatter, and intense heat generated during welding or cutting.

Welding blankets are made from flame-retardant materials like fiberglass, silica, or vermiculite-treated fabrics. These materials can withstand temperatures ranging from 1,000°F to over 2,000°F, depending on the specific type of blanket.

Why Every Workshop Needs a Welding Blanket

Fire Prevention: Sparks and molten metal can ignite flammable materials nearby. A welding blanket provides a critical line of defense.

Workplace Safety: Shielding equipment and flooring from heat damage helps maintain a safer environment.

Versatility: Welding blankets can be draped, hung, or wrapped around equipment, making them adaptable to various tasks.

Reusable and Durable: With proper care, high-quality blankets can be used multiple times, making them cost-effective over the long run.

Whether you're working in a garage, a fabrication shop, or a construction site, a welding blanket ensures that your workspace stays safe and undamaged.

Combining the Nitrogen Gas Regulator and Welding Blanket in Practical Applications

The true value of these tools shines when they are used together. For example, during HVAC installation or repair, technicians often use nitrogen to pressurize lines or purge them before brazing. While the nitrogen gas regulator ensures a clean and controlled flow of gas, the welding blanket protects nearby components from heat and flame during brazing.

Similarly, in industrial maintenance, nitrogen is often used to displace oxygen and prevent oxidation inside systems. At the same time, welding blankets can protect sensitive instruments or flammable materials in the vicinity. This combination of tools allows professionals to work more confidently, knowing that both internal and external safety measures are in place.

Tips for Using a Nitrogen Gas Regulator and Welding Blanket Effectively

Always Inspect Before Use: Check for leaks, wear, or damage on both your nitrogen gas regulator and welding blanket before starting any job.

Know Your Pressure Requirements: Set the regulator according to the specific task—over-pressurizing can be as harmful as under-pressurizing.

Secure the Blanket: Make sure the welding blanket is properly anchored or draped to cover all necessary areas.

Store Properly: When not in use, store both items in dry, cool locations to extend their life.

Conclusion

Professionals across multiple industries rely on safety, accuracy, and efficiency to get the job done right. The Nitrogen Gas Regulator and Welding Blanket may not always take the spotlight, but they are essential tools in achieving those goals. A nitrogen gas regulator helps maintain optimal pressure levels during gas operations, while a welding blanket shields surroundings from dangerous sparks and heat.

Using both tools correctly ensures your job site remains safe and your work meets the highest standards of quality. Don’t overlook their importance—equip yourself with the right tools and set your projects up for success. Report this page